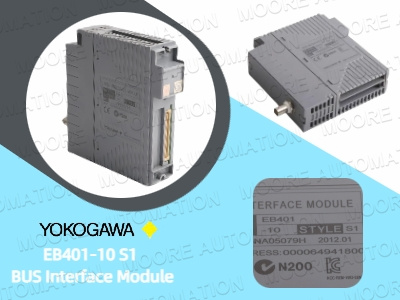

Introduction: What It Is In today's industrial automation environment, the ability to quickly and stably exchange data between devices directly determines the efficiency and reliability of system operations. To meet this demand, Yokogawa has launched the EB401-10 S1 bus interface module, a communication unit specifically designed for the ER bus platform. Measuring only 3.1 × 14.3 × 13 cm and weighing 0.26 kg, the module delivers 10 Mbps data transmission via a BNC interface, with a maximum communication distance of 185 meters. It also consumes only 0.7 A of current during operation, offering excellent energy efficiency. Serving as a bridge in industrial control networks, the EB401-10 S1 connects field devices to distributed control systems, ensuring efficient and stable information transmission. Its modular design allows for seamless integration into existing systems, providing users with a flexible and scalable communication solution. Advantages and Features The EB401-10 S1 offers multiple advantages in industrial applications: Fast Data Exchange Supporting a 10 Mbps communication rate, it enables near-real-time signal transmission. During chemical plant operation, critical parameters such as temperature and pressure can be quickly uploaded to the control end, shortening response time and ensuring more precise control. Long-Distance Transmission Compared to traditional interfaces, which are limited to a few dozen meters, this module supports a transmission range of 185 meters. This allows the control room to directly manage remote equipment, eliminating relay equipment and reducing wiring and maintenance costs. Energy Efficiency Optimization Power consumption management is particularly important in long-term industrial sites. The module requires only 0.7 A of current for stable operation, reducing system energy consumption and heat buildup within the cabinet. Compact Design The module's compact and lightweight design allows for flexible installation, making it easy to deploy even in control cabinets with limited space and facilitating subsequent maintenance. Stable Bus Compatibility The EB401-10 S1 uses a BNC connector, ensuring stable and reliable signal transmission, maintaining a stable connection even in industrial environments subject to strong electromagnetic interference or frequent vibration. These features make this module an ideal choice for users who prioritize communication reliability, efficiency, and energy efficiency. Application Scenarios The EB401-10 S1 serves a variety of industrial sectors: Process Manufacturing In the chemical, pharmaceutical, and petrochemical industries, parameters such as temperature, flow, and pressure require real-time collection. This module rapidly uploads distributed sensor data to ensure stable process operation. Energy and Utilities In power plants and water treatment plants, equipment is often distributed over a wide area. Leveraging its 185-meter transmission capacity, a central system can effecti...

Read More

IPv6 network supported

IPv6 network supported